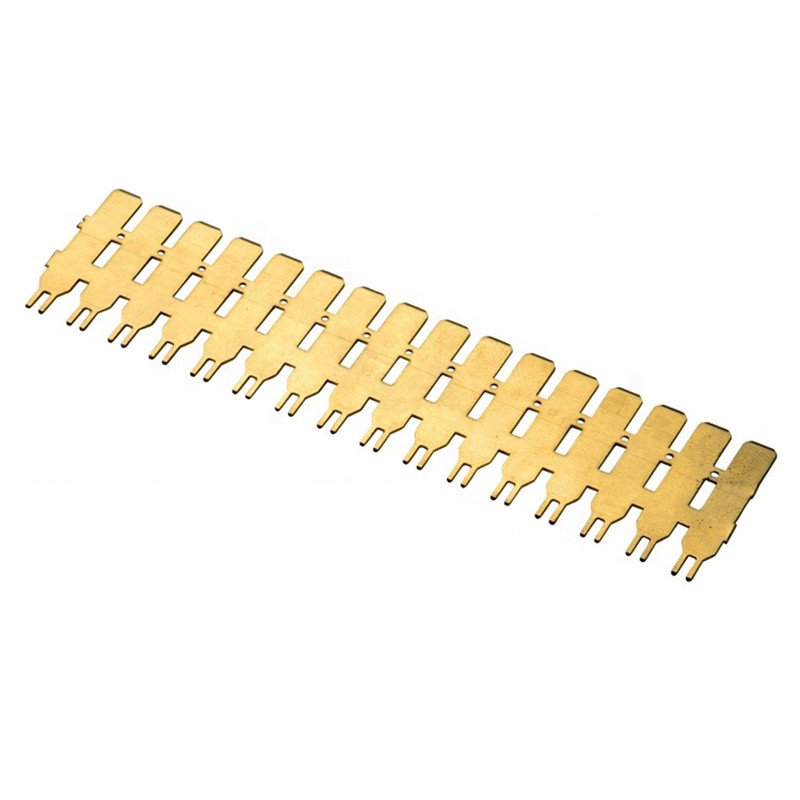

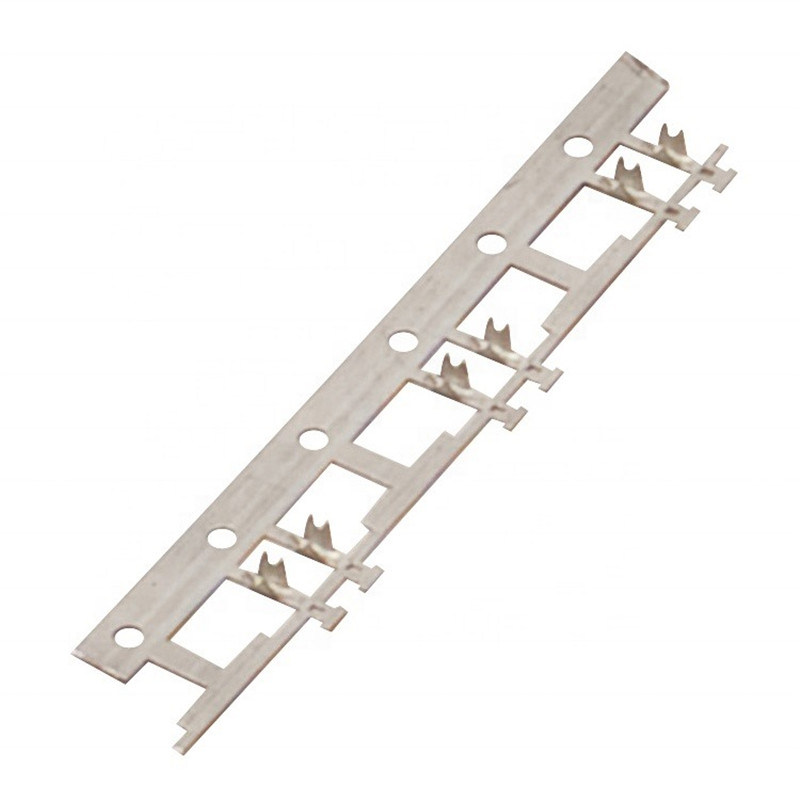

Custom Stamping Bronze Metal Crimp Wire Terminal _ Terminal Blocks_

Our advantages

* We have Professional R&D Team,design and manufacture our own tooling;

* Reidal's expert engineers can help optimize your design for manufacturability and assist in reducing overall cost;

* We have 10 years more experiences for exporting to Europe and USA;

* We passed ISO 9001:2015,and are working for IATF16949 audit.

* We have written working instructions for each product and each machine,All operations are implemented exactly according to the SOP.*100% Full inspection;

Product Description

| spec: | Metal Stamping Wire Connector Terminal |

| surface treatment: | gold,silver,tin,nickel,zinc,chromium,copper-plating,laser etching,screen printing,phosphating(can pass salt spray testing,electrophoresis,passivating,deburring,polishing,brush according to rohs standard |

| Material: | brass,copper,stainless steel,roll steel etc |

| color: | Tin plated, nickel plated, silver plated, gold plated |

| package: | plastic bags,reel,export carton and any other customized package according to the customers requests |

| Test: | salt and spray test,tensile test et |

| application: | all different kinds of telecom products,automotive,high-end digital cameras,medical equipment,remote,washing machines,vacuum cleaners,desk lamp,furniture,swich power supply,socket,water heater,high-end toys,calculator,electrical,inrerphone,wireless mouse,wifi router,cordless telephone,mobile,mobile dvd,sounder.Auto clutch,bicycle brake,scooter and so on |

| quotation: | please provide the formal drawings(nomally,with dwg,stp,pdf,file)and make note with material,quantity,surface treatment and any other requirements,we will provide you the quotation sheet in 24-72 hours |

We have the resources to build a die for any application. When high volumes of production are expected, we can build a dependable tool with longevity in mind. We can also produce low-cost tools for prototyping and sampling applications. Die protection is always on our mind, and DACO Precision-Tool can build in sensors that will help prevent costly damage to the die.

Metal stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produce the desired form on the sheet metal part, or could occur through a series of stages.

If you need full custom design and production service, Reidal can also ensure that your very specific needs are met. Whatever your industry, whatever your application, We custom design and manufacturing process means engineered solutions designed to your exact demands. Start to finish, from conception through delivery, we ensure that specifications are met and your product is up to all possible standards. Every part that leaves our facility is the result of precision