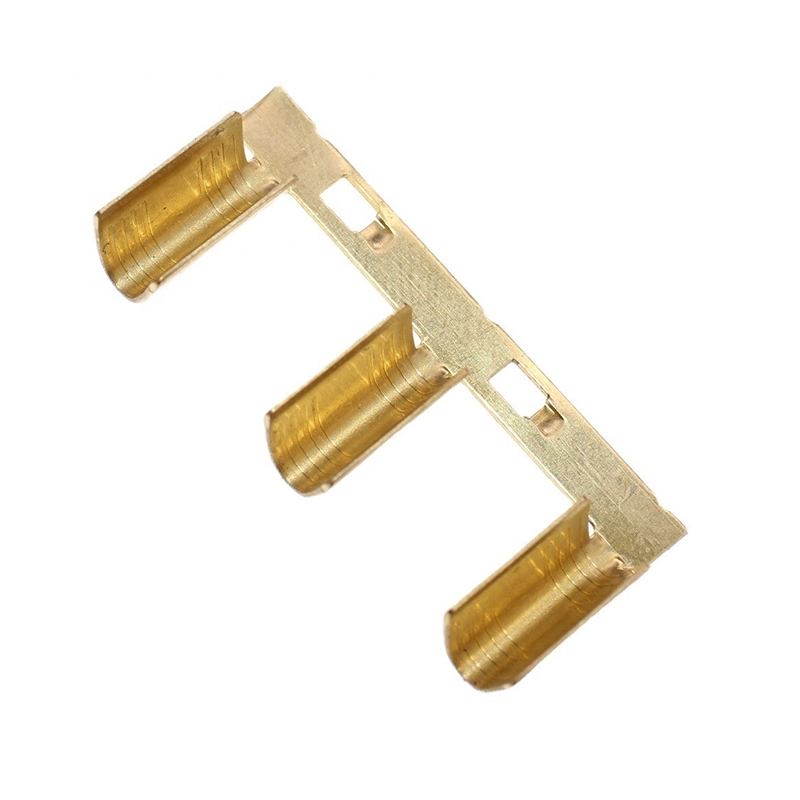

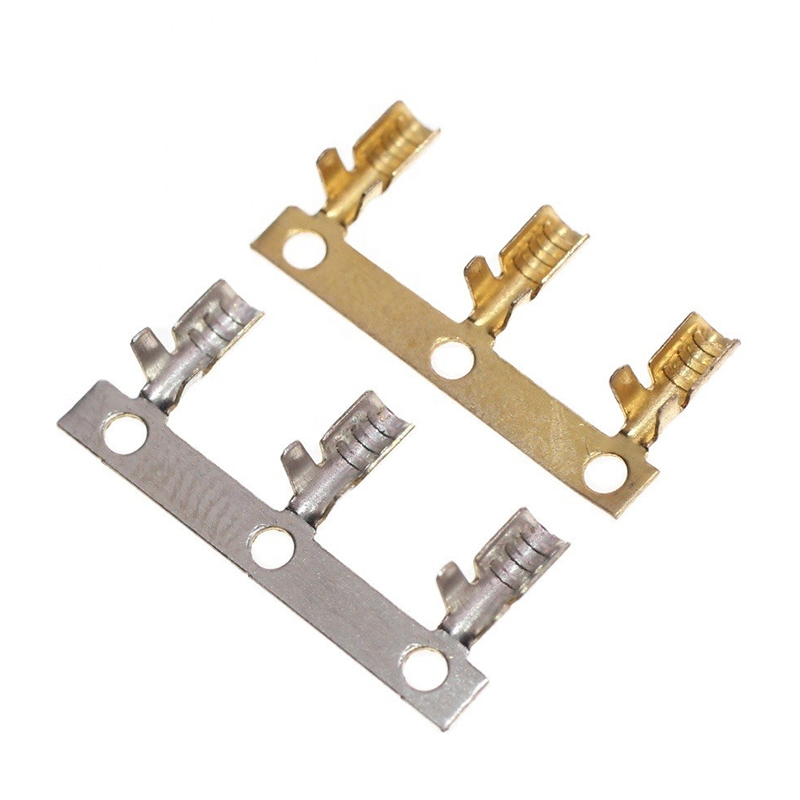

Mini Nickle Plated Brass Wire Double U Shaped Electrical Crimp Terminal Connector Block

Stamping Capability

A: The min. pitch: 0.5mm

B: Highest stamping speed: 600SPM/min or more

C: Precision: ±0.003mm

D: Rate of hole diameter and thickness 0.85:1

E: Stamping material thickness:0.05-2.0mm

F: zero or less loss of material use.

Features

Utilize the existing track-type terminal RTB connection technology, and install a circuit composed of electronic components to realize the transmission coupling of the photoelectric process. The core of automatic control is that the control unit must be reliably isolated from the sensors and actuators to avoid interference. The terminal can perform this function well and ensure that the field signal matches the low voltage required by the electronic control device.

It is the interface component between peripheral equipment and control, signal and regulator device for process control, and is suitable for different voltage and power ranges. The optical isolation terminal has the advantages of low signal loss at the control end, high switching frequency, no mechanical contact jitter, no wear switching, high insulation voltage, no vibration, no positional influence, and long life. Therefore, it is widely used in the field of automatic control.

Features

| 1.Material | Copper |

| 2.Application field | Electrician electrical/Industrial Equipment |

| 3.Surface treatment | According to customer needs:tin plating,nickel plating,silverplating,gold plating |

| 4.MOQ | Small order can be accepted |

| 5.R&D ability | Make new terminals according to customer samples or drawings |

| 6.Delivery time | Conventional terminal for about a week |

| 7.Qulity control | All goods well be 100% inspected before dispatched |

| 8.Company Type | Factory and trade integration,12 years export experience |

| 9.Certificates | ISO9001 ISO14001 SGS ROHS CQC REACH |

| 10.Test | High temperature,Salt sprayl,waterproof |

| 11.Package | 100/200/300/500/1000 per bag with label,then with standard carton |

Customized Products service Free Customized Design Sample Any Custom Logo, size, shape is acceptable.

1. Customers provide samples or required product drawings

You can provide us with drawings and samples of a certain product according to your own needs

2. Technical disassembly drawing analysis and testing whether it can be produced

Our engineering department disassembles the drawing analysis to confirm whether it can be produced

3. Determine if it can be produced

If it can be produced, the project will analyze the required material and material specifications according to the drawings provided by the customer, the required mold tonnage, and the production capacity that can be achieved to the business.

4. Business Quotation

The price of comprehensive business materials (PMC will confirm the price with the supplier), the price of surface treatment (the PMC department will confirm the price with the supplier) and other accounting costs before quoting to the customer

5. There is no objection to the price, make a sample to the customer for confirmation

If the customer agrees with our quotation, the mould will be made, a small number of samples will be produced, and the samples will be sent to the customer for confirmation

6. The samples are confirmed to be correct, and the contract is signed for mass production

After the sample is confirmed by the customer, the contract is signed for mass production.

7. Arrange for factory production--packaging--warehousing—shipment

What Are The Four Main Types of Termination Available ?

(1) Ring terminals are the most common. The ring on the end of the terminal is attached to a

threaded stud and held in place with a nut. There are different size ring holes (or studs)

depending on the equipment.

(2) Spade terminals look like a two pronged fork. The advantage of a spade terminal is that

you can attach them to a stud without completely removing the nut. Just loosen the nut,

insert the spade terminal, and re-tighten. Some spades have a locking mechanism or

bent flange that holds the spade in place even when the nut is loose.

(3) Disconnect terminals slide in and out of each other. Naturally, one is female and one is

male. These are used when the connection needs to be disconnected frequently. It is

easy to slide the disconnect terminal on or off. Some disconnects are “fully insulated” so

that no part of the connection is exposed after pushing the two together.

(4) Butt splices are simple tubes that are used to connect two pieces of wire. One piece of

wire is inserted into each side of the butt splice and the wire is crimped on each side.

This is especially helpful to reconnect a wire that is accidentally cut.

(5) There are other specialty terminals as well. Ferrules, piggy back, snap plug etc. Contact

elecDirect.com for information or application advice on these products