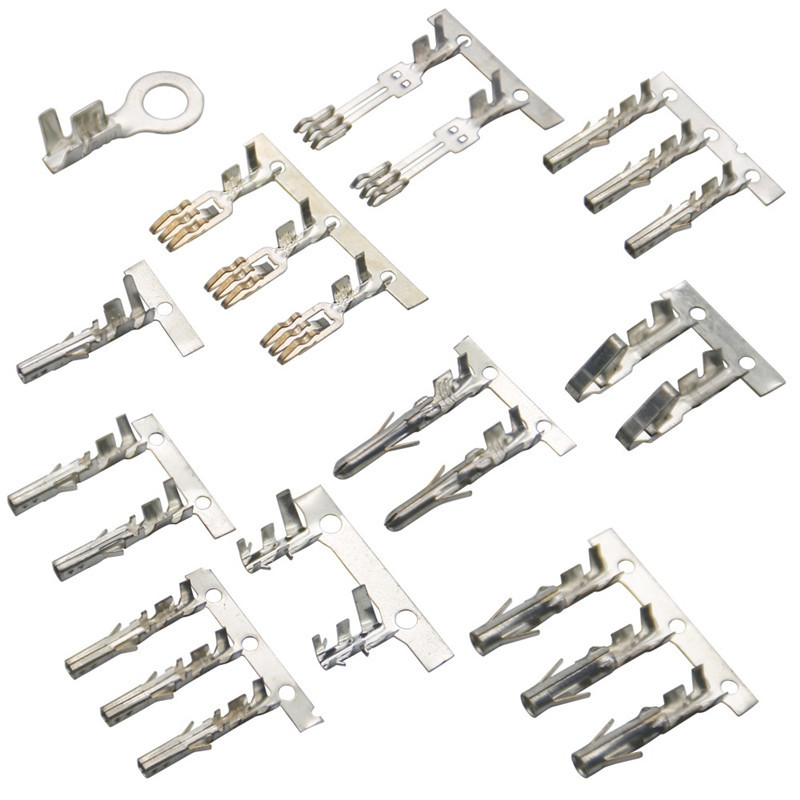

Newly Arrival Ethernet Connector Block - Crimp Terminal Brass Terminal Connector 4.2mm 2.54mm 2.5mm Pin Female Metal Small 4P Metal Stamping Wire Connector Terminal – Weiting

Newly Arrival Ethernet Connector Block - Crimp Terminal Brass Terminal Connector 4.2mm 2.54mm 2.5mm Pin Female Metal Small 4P Metal Stamping Wire Connector Terminal – Weiting Detail:

Product Description

Terminals are necessary to connect various circuits or systems. Sometimes called electrical connectors, these components are used to transfer electrical current from a power or grounding source to an electrical system.

In modern devices, almost all internal systems are controlled by an array of electrical terminals and connectors. These increasingly complex components manage a variety of functions while delivering critical feedback in real-time.

Optimize device performance with high-quality terminals from Wiegel. We are an industry-leading supplier of stamped metal parts and assemblies for use in a variety of industries, and we specialize in precision terminals for demanding applications.

| Product Name | sheet metal stamping parts |

| Services | OEM/ODM |

| MOQ | 10000pcs |

| Material | brass, phosphor copper, beryllium copper, stainless steel SUS304/301, etc. |

| Surface Treatment | Tin plating, nickel plating, silver plating, gold plating, etc. |

| Shape | N type, U type, W type, L type, etc. |

| Color | material primary color, gold, silver, black,etc. |

| Oxidation test | salt spray test |

| Production equipment | Production equipment imported from Japan, and independent research and development design and mold making; High-speed precision continuous punching machine and high-speed electric injection molding machine |

| Testing equipment | advanced high-precision projector, 2.5-dimensional tester and other high-standard, tool magnifying glass, microscope, tensile tester, hardness tester, ROHS tester and other testing equipment |

| Certification | UL,SGS, MSDS, CE, ISO9001,ROHS,REACH, CQC,TUV,PAHS,PFOS,PFOA |

| payment method | T/T, Paypal, L/C, Western Union |

| Package | Plastic bag+Carton Box |

| Spot delivery | 3-5 days |

| Batch order delivery time | 7-15 days or negotiation time |

QUALITY ASSURANCE

the quality of the parts leaving our facility is our highest priority. We conduct a feasibility review on the part to ensure manufacturability at the start of every program. A run-at-rate study is implemented on the first run to ensure quality before large-scale production. This enables our quality and production management teams to monitor controls closely and ensure the job runs smoothly. Manufacturing continues once testing checks out, and the first batch of conforming parts is produced.

Our quality management system is comprised of sophisticated quality technology and controls, continuous improvement programs and a superior quality laboratory and management team. Throughout our production plant, we deploy in-line/off-line camera vision systems and sensor technology, in which we design and fabricate unique to every production program. Our vision system technology operates in coordination with our stamping production machinery to thoroughly inspect and identify part features and dimensions with automated camera imaging. This quality control process ensures every part produced with our stamping equipment always yields 100% quality and zero defects.

Our company supplies different kinds of products. High quality and favorable price. We’re pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

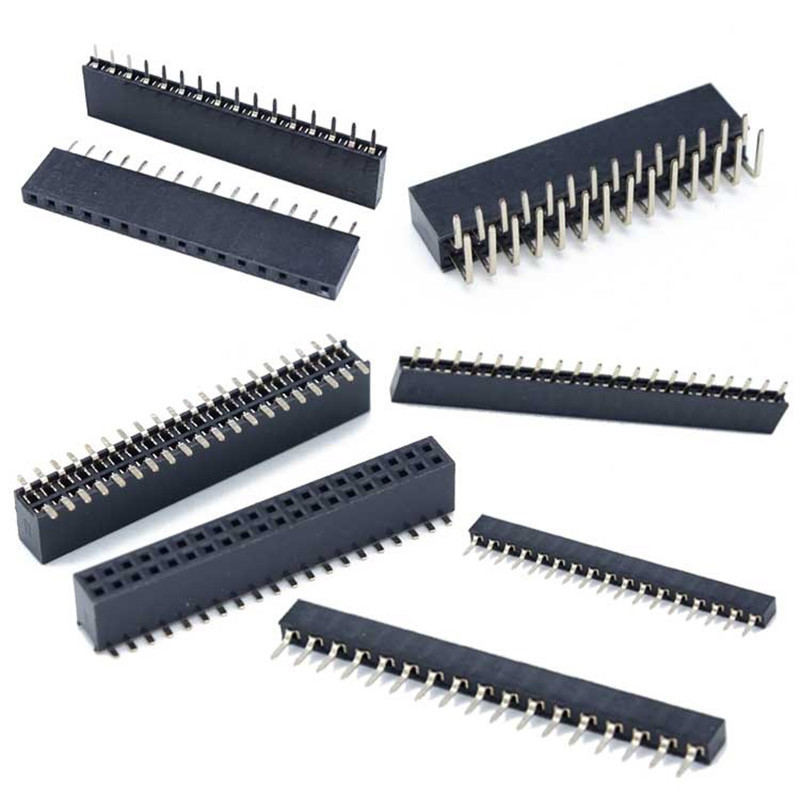

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Newly Arrival Ethernet Connector Block - Crimp Terminal Brass Terminal Connector 4.2mm 2.54mm 2.5mm Pin Female Metal Small 4P Metal Stamping Wire Connector Terminal – Weiting , The product will supply to all over the world, such as: Madagascar, Plymouth, Orlando, Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.