Precision Metal Stamped Brass Super High Pin 4.2mm Terminal

1. Material Red Copper

2. Application field Electrician electrical/Industrial Equipment

3. Surface treatment According to customer needs:tin plating,nickel plating,silver plating,gold plating

4. MOQ Small order can be accepted

5. R&D ability Make new terminals according to customer samples or drawings

6. Delivery time Conventional terminal for about a week

7. Qulity control All goods well be 100% inspected before dispatched

8. Company Type Factory and trade integration,12 years export experience

9. Certificates ISO,RoHS,SGS,CQC

10. Test High temperature,Salt sprayl,waterproof

11. Package 100/200/300/500/1000 per bag with label,then with standard carton

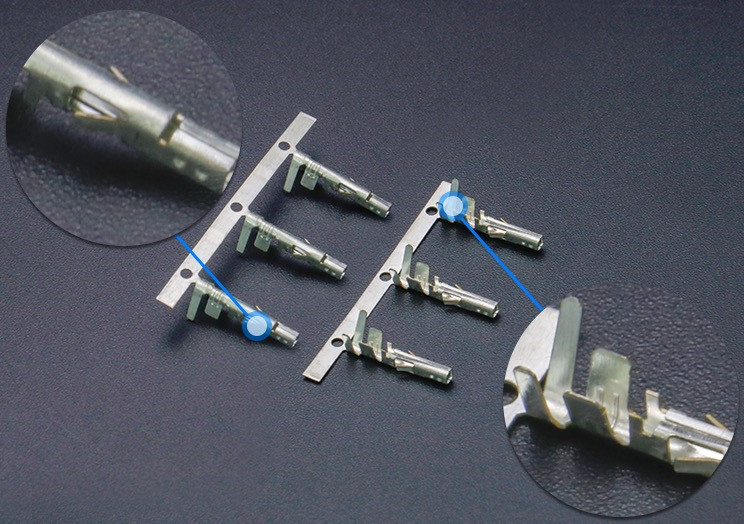

Our tab terminals are stamped from a continuous strip of material with the use of precision, progressive dies and then postplated to provide optimum solderability and corrosion resistance. PCB tab terminals are then reeled ready for machine insertion. They are designed for use in the automotive, electrical, telecommunications and electronics industries.

The capabilities and variety of our metal stamping presses, our expertise in tooling design and engineering, coupled with continuous improvements in manufacturing driven through our ISO/TS 16949 quality standards, ensure competitive pricing and shorter lead times within our global manufacturing footprint.

Our equipment list features more than 42 Bruderer presses covering ranges from 15 ton to 100 ton presses. This diversity of equipment ensures we will always have the perfect press for your particular global application.

Product Description

| Product Name | Terminal Connector |

| Services | OEM/ODM |

| MOQ | 10000pcs |

| Material | Brass, phosphor copper, beryllium copper, stainless steel SUS304/301, etc. |

| Surface Treatment | Tin plating, nickel plating, silver plating, gold plating, etc. |

| Shape | Can be customized according to customer needs |

| Color | Material primary color, gold, silver, etc. |

| Oxidation test | Salt spray test |

| Electroplating | First punching and then plating, first plating and then punching |

| Production equipment | Production equipment imported from Japan, and independent research and development design and mold making;High-speed precision continuous punching machine and high-speed electric injection molding machine |

| Testing equipment | Advanced high-precision projector, 2.5-dimensional tester and other high-standard, tool magnifying glass, microscope, tensile tester, hardness tester, ROHS tester and other testing equipment |

| Certification | UL,SGS, MSDS, CE, ISO9001,ROHS,REACH, CQC,TUV,PAHS,PFOS,PFOA |

| payment method | T/T, Paypal, L/C, Western Union |

| Package | Plastic bag+Carton Box |

| Spot delivery | 3-5 days |

| Batch order delivery time | 7-15 days or negotiation time |